Lining with plastic sheets

Lining basins or tanks with plastic sheets forms an insulating layer for existing steel basins or tanks. This technology is a sustainable solution for the lining of tanks, silos and basins used in the automotive industry. PP-H sheets are attached to defined points on the steel wall to be coated. This results in a high degree of elasticity so that the different expansion coefficients of the steel and polypropylene materials are equalised in the event of temperature fluctuations.

Benefit from our experience in the field of lining with plastic sheets and contact us for the planning of new basins and tanks or for the refurbishment of existing systems.

Do you have any questions?

Please give us a call. We provide you with competent and reliable advice and use our expertise to implement your wishes on time.

Telephone: +49 (0) 821 – 600 550 Email: info@ekk-anlagentechnik.deAdvantages of lining with plastic sheets (PP-H):

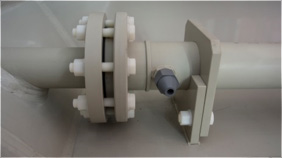

Due to the excellent chemical resistance and very good paint compatibility of polypropylene (PP-H), PP-H sheets are ideal for plastic linings for basins and tanks. The smooth surface of the material means that there is hardly any paint build-up, so there is no need for regular cleaning intervals. Our leakage monitoring system indicates any leaks in the basin quickly and reliably via the fill level, so that no annual pool inspections are necessary to detect damaged areas.

Lining the existing tank or basin using the "loose shirt" method creates a double-walled system, which results in a high level of system safety. Any leaks that occur are indicated in the leakage monitoring system – visually or electrically. Such leaks or damaged areas can be easily detected and repaired. Time-consuming draining and drying of the basin is not necessary and the system is quickly available again.

The accessories and attachments made of PP-H required in a CDC basin, such as flood tubes, crash rails, mounting systems for bottom tubular dialysis cells or free anodes, can be welded on without any problems. In addition, the flow-optimised design of the built-in components ensures an improved bath flow and optimum bath circulation in the CDC basin.

Lining with plastic sheets by EKK

EKK does not provide you with a standard solution. Every basin is different and each of our solutions is customised to your needs. We take care of the entire project work and provide you with a complete solution from a single source: We take care of every step of the process, from measuring the basins on site to engineering, prefabrication, final assembly and commissioning.

All our employees have specialist expertise and practical experience in lining with plastic sheets. Thanks to our expertise in the field of plastic linings, we know the needs of our customers in the automotive industry, the pharmaceutical industry and the general industry. Our work incorporates the current state of development and the expertise of our employees through their work with in-house production or on-site assembly. Because of this, we are constantly simplifying our production processes and also rely on resource-saving production machines. In order to offer the best possible service and ensure effective processing, we at EKK emphasise flat hierarchies and rely on a constant exchange between the individual departments.

All parts are produced in our production facilities in Friedberg and Ziemetshausen. In the interests of the most sustainable production possible, we pay attention to waste-optimised processing of plastic sheets. We have state-of-the-art processing machines at our disposal for this purpose, such as our CNC milling machine with nesting software.

The advantages of EKK Anlagentechnik at a glance:

- Many years of experience and expertise

- Plastic lining from a single source (from acquisition to commissioning)

- Made in Germany (production in Friedberg & Ziemetshausen)

- Qualified specialist staff

- Flat hierarchies

- Motivated employees

Plastic lining: Procedure & implementation of the projects

Careful lining of basins or tanks with plastic sheets requires detailed project planning. In order to prepare an appropriate quotation, we require the following from our customers:

- Construction drawings of basins or tanks

- Empty process basins or tanks for detailed measurements

- Process parameters (chemical compositions of the media, process temperature)

- Type of mechanical stresses

Lining with plastic sheets – a sustainable solution

A tank or basin lining with PP-H sheets is a durable and extremely sustainable product. Analyses of our sheet material, which had been in use for 8 years in a CDC bath, showed hardly any material fatigue in the sheet samples.

| Inspection | Standard | Unit | Value |

|---|---|---|---|

| Density | ISO 1183 | g/cm³ | 0.92 |

| MFR – 230°C 2.16 kg | ISO 527-1 | g/10 min | 0.30 |

| Notched impact strength | ISO 179 AE1 | mJ/mm² | 6.12 |

| OIT 210°C | min | 28.60 | |

| DSC | DIN EN ISO 3146 | °C | 166.20 |

The values for density and DSC correspond to those of new material.

The requirements for melt flow index MFR and notched impact strength for extruded polypropylene sheets are defined in section 4.3.1 Table 2 of DIN EN ISO 15013. The MFR for Group 1 should be between 0.2 – 0.7 g/10 min. The notched impact strength is > 6 kJ/m². For the OIT measurement, our PP sheet supplier defines a value of > 20 for new material. The tested sheet material fulfils this requirement even after several years of use.

Flood pipes with nozzles

Flood pipes with nozzles support the coating circulation in the CDC basin. This mixes the coating evenly and prevents pigment sedimentation. We manufacture the flood pipes customised to the respective basin geometry and equip them with the appropriate number and type of nozzles according to customer requirements.

- Material: PP-H

- EKK mounting system with inliners for installation on the basin floor and basin wall

- Available nozzles: Pointed nozzles | Mixing injector nozzles | Cone nozzles

- Ball joint system for nozzles

Crash rail

Crash rails are used to protect fittings in the event of falling car bodies or opening car doors and boot lids. We install appropriate crash rails in front of the dialysis cells on the basin wall or above the additional anodes and flood tubes on the basin floor.

- Material: PP-H

- EKK mounting system with inliners

Frequently asked questions on the subject of lining with plastic sheets:

For which areas is the lining with plastic sheets suitable?

Lining with plastic sheets is suitable for basins and tanks made of metal and concrete. The technology is used wherever process basins are used, e.g., in the automotive industry, the pharmaceutical industry and general industry.

Depending on the order, EKK Anlagentechnik undertakes the refurbishment of existing systems or the plastic sheet lining of new tanks and basins.

How long does it take to install plastic sheets on site?

The duration of the installation always depends on the individual project and the local conditions. Depending on the size of the basin, installation on site takes between 10 and 12 days. Naturally, we endeavour to minimise production downtime for our customers and adapt to their production times.

We can often perform our work during the annual production shutdowns. Depending on the complexity and schedule of our customers, we perform the installation in one or two shifts.

In which countries does EKK Anlagentechnik implement the lining with plastic sheets?

Our production facilities are located in Friedberg and Ziemetshausen. Due to transport routes and in the interests of sustainability, we focus on lining with plastic sheets in Europe, primarily in Germany and its neighbouring countries. If required, we can, of course, also provide you with a corresponding offer outside these countries.

Does EKK Anlagentechnik also line old tanks with plastic sheets?

Yes, EKK Anlagentechnik also lines old tanks with plastic sheets. The prerequisite for this is an intact statics of the object. Our aim is to preserve the existing tank and to restore the mechanical and chemical resistance of the tank and, if necessary, the electrical insulation.

When is lining with plastic sheets required?

Lining with plastic sheets is in demand when planning new basins and tanks or for the renovation of existing systems. EKK is often called in as part of the refurbishment of existing basins.

The advantages of lining with plastic sheets are, on the one hand, increased system availability and, above all, the excellent chemical resistance of the plastic used. In the event of a leak, the repair work can be carried out directly at the leakage point. There is no additional production downtime for drying or material curing.