Systems engineering

EKK stands for customised solutions, with our customers’ requirements and wishes taking centre stage. We are your partner for process-optimised planning and design of your systems concepts.

Many years of experience and trusted cooperation with our customers form the foundation for a holistic approach to both the revitalisation of existing systems and the construction of new production systems. For further development of products and processes in paint shops, great importance is attached to energy efficiency as well as increasing quality and optimising costs.

We offer you support in the planning, design and implementation of painting systems for car bodies and pre-treatment:

Exhaust air and waste water treatment

Storage tanks, including filling and measurement accessories

Basin and tank linings

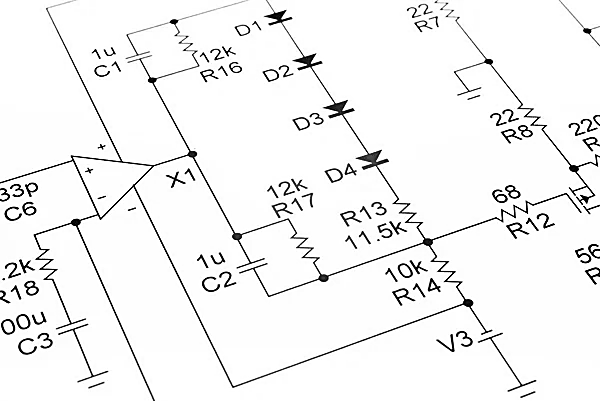

Cathode dip coating (CDC) technology and anolyte systems

Process engineering for water treatment

The topic of water and the associated process engineering for water treatment and improvement of water quality encompasses our entire lives, on which the state of our health, environment and prosperity depends.

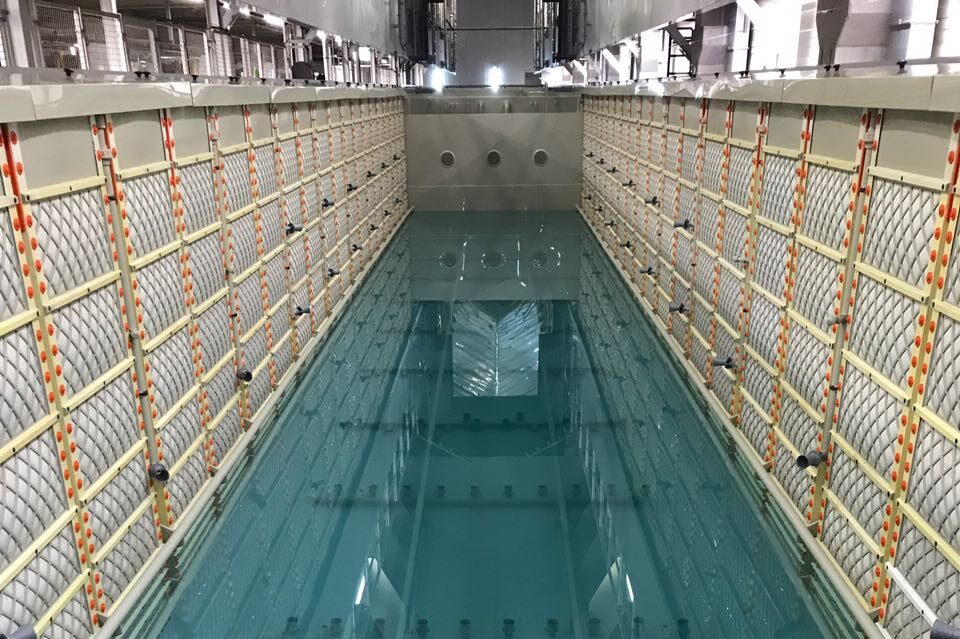

Lining with plastic sheets

Lining basins or tanks with plastic sheets forms an insulating layer for existing steel basins or tanks. This technology is a sustainable solution for the lining of tanks, silos and basins used in the automotive industry.

Coating with plastic resin

Coating basins and tanks with plastic resin forms an insulating and protective layer. In this so-called laminate spray coating, a reactive resin is applied to the material to be coated.

Cathode dip coating

Cathode dip coating, or CDC for short, is an electrochemical coating process in which components are coated with an electrically conductive, aqueous dip coating in an immersion bath.