CNC milling work

As an established company in the field of high-precision milling technology, we have modern CNC milling machines at our disposal to actively support you with your projects at all times. State-of-the-art CAD/CAM control systems and the many years of experience of our excellently trained employees allow us to support you from design and planning through to production.

As a manufacturing service provider, we undertake milling work of all kinds with the highest care, absolute precision and the greatest possible flexibility. Benefit from our many years of expertise and the complete implementation of your concepts from a single source at our locations in Friedberg and Ziemetshausen.

CNC milling work: Made in Germany – from the idea to series production

Thanks to flat hierarchies and direct contacts, we offer you maximum flexibility and maximum efficiency throughout the entire development process for your milled parts made of plastic and other materials. We support you right from the brainstorming stage, enrich your project with our expertise and, on request, take over the conceptualisation and design of your components from our in-house design department.

Our design engineers use the latest CAD programs to implement your ideas in the best possible way and according to your individual wishes. The integration and further development of advanced CAD/CAM process chains ensures maximum attention to detail and automated workflows throughout the entire production process in CNC contract manufacturing.

3-axis CNC milling and 5-axis milling for demanding workpieces

While CNC milling machines with computer-aided machine control already guarantee maximum precision and accuracy, production using 5-axis simultaneous milling operations poses a particular challenge. The production of components with an accuracy of +/- 0.05 mm promises a precise fit for every conceivable application. Our state-of-the-art machinery enables us to produce sophisticated free-form surfaces and ensures optimum raw material utilisation thanks to the latest nesting software as well as a significant reduction in manual post-processing of the finished components.

We perform both milled parts made of plastic and milling work on workpieces made of materials such as steel, non-ferrous metals and brass competently and professionally for you at all times. Thanks to our large stock of a wide range of raw materials, we offer shorter delivery times and a rapid response to your special requirements in contract manufacturing.

You can have your components manufactured by us and be sure of receiving fully tested workpieces for each of your projects, which are subject to our strict quality standards and continuous monitoring processes. Our aim is to provide you with the best possible advice in every respect and to support you as a trustworthy and competent partner for CNC milling work.

CNC milling work from a single source

Since EKK Anlagentechnik was founded, our company has been writing a success story, which we attribute to our strict quality controls, short delivery times and flexibility. By taking action proactively, we offer and maintain a modern working environment with highly trained employees at all times on the latest CNC milling machines, who make a significant contribution to our company's success.

It is our company philosophy to make each of your projects our own. We place great importance on open communication and lively dialogue in order to achieve optimum results and meet your requirements at all times.

So please feel free to contact us. We look forward to actively supporting you with your project.

Frequently asked questions about CNC milling:

Which workpieces can be produced with CNC milling?

A CNC milling machine can be used to produce technical components, machine parts, free-form parts, art and design parts with complex shapes and in a wide variety of designs. This enables us to fulfil the high precision requirements and quality demands of the industry.

It is possible to mill workpieces with different contours, chamfers, pockets and grooves in five different axes.

Even production parts with complex drilling and tapping patterns can be executed with precision and repeat accuracy. Furthermore, panel formats can be precisely formatted, edged and drilled.

What materials can a CNC mill process?

Numerous materials can be processed with a CNC milling machine, such as:

- Thermoplastics and thermosetting plastics

- Foams

- Composite materials

- Insulating materials

- Wood

- Non-ferrous metals

- Various steels

What are the advantages of 5-axis CNC milling?

A 5-axis mill offers more adjustment options, such as the angle and machining directions. Simultaneous milling strategies and axis rotations are also possible.

Shape and position tolerances are extremely low, as the raw material is only clamped once and processing is carried out from almost all sides of the component.

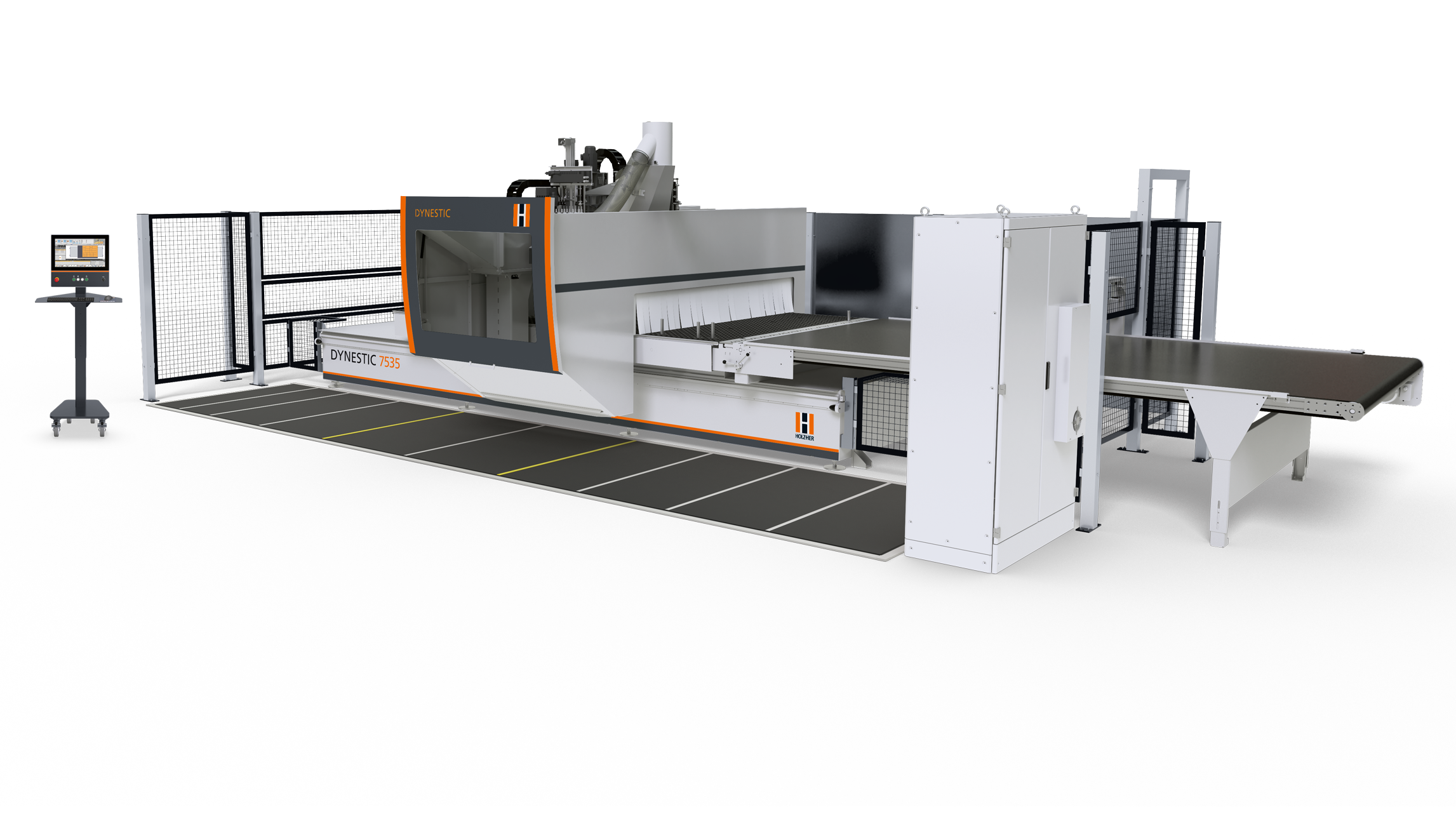

Which machines does EKK Anlagentechnik use for CNC milling work?

- 3-axis milling machine: VHF 2040 Active Pro

- 5-axis milling machine: Wood-Her Dynestic 7535 push

- As well as other machining centres

How precise is a CNC milling machine?

A CNC milling machine works with an accuracy of +/- 0.05 mm.