Exhaust air scrubbers | Exhaust air technology

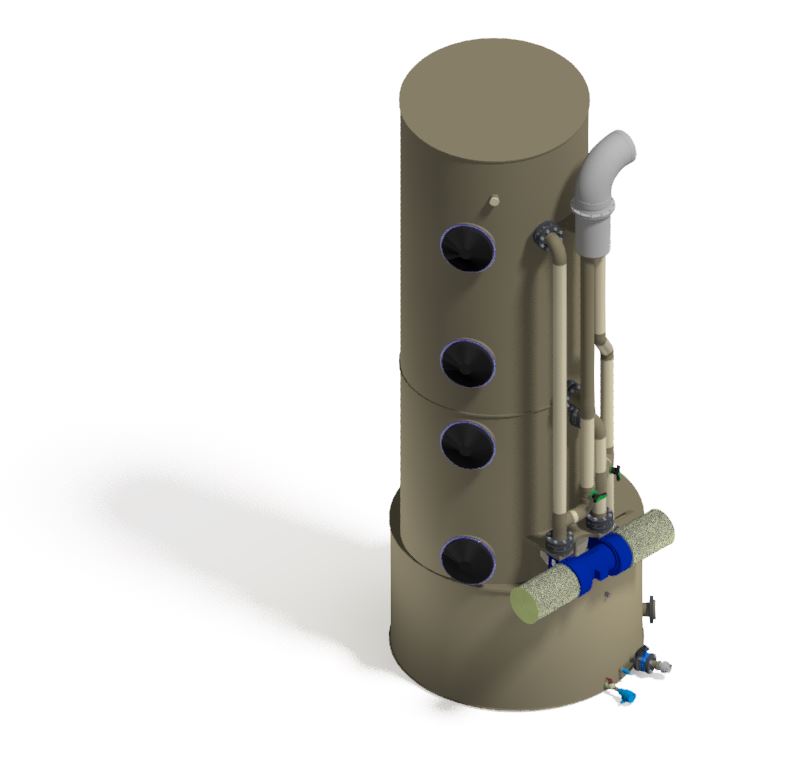

Exhaust air scrubbers, also known as gas scrubbers or absorbers, are equipment that are used for mass transfer. In this process engineering method, a gas stream is brought into contact with a liquid stream in order to absorb components of the gas stream into the liquid. The components of the gas flow can be solid, liquid or gaseous substances. A gas scrubber can be used simultaneously to separate solids and as an exhaust air scrubber.

Areas of application for absorbers:

- Neutralisation of exhaust air with water

- Treatment of water to demineralised water

Ion exchanger

Normal city water is not chemically pure water. Various positively charged cations and negatively charged anions are dissolved in the raw water. In complete demineralisation using the ion exchanger process, the raw water is passed through a cation exchanger and an anion exchanger.

These ion exchangers are columns containing a resin filling with adhering cations and anions. This resin filling absorbs the cations and anions to be dissolved out of the raw water at the surface and releases the ions bound to the columns in return. This allows cations such as Ca²⁺ or anions such as HCO3– to be removed from the water and thus, softened. They are used in particular to prevent limescale precipitation in feed water tanks or heating elements. The resins become increasingly loaded with foreign substances from the wastewater and must be regenerated at adjustable load values with the aid of concentrated anion or cation solutions (e.g., HCl, NaOH). A redundant design of the ion exchangers must be provided for continuous production of demineralised water.

EKK-Anlagentechnik also offers CO2 strippers and membrane degassing systems for the application of freely dissolved carbon dioxide or oxygen and the associated increase in the service life of the ion exchanger or membrane systems.

CO2 stripper

This container is used to physically expel the carbon dioxide dissolved in the water. This phenomenon is achieved by atomising the water and adding a counter-current flow of air in a layer of packing. The oxygen content of the water increases until it is saturated and the carbonic acid can escape from its dissolved form as HCO3– into the gaseous CO2. This reduces the conductivity of the water.

Membrane degassing

In membrane degassing, free carbon dioxide or oxygen is also extracted from the water. This phenomenon is based on the Venturi principle. The water in a hollow fibre module is exposed to a counterflow of air in the outer area, which absorbs the gas diffused from the membrane in the inner area and transports it away.

The reduced operating costs, lower chemical consumption (in the ion exchanger process) and the compact design are offset by the higher investment costs compared to a CO2 stripper filter. It is mainly used in ion exchangers and reverse osmosis.