Current collectors

Current collectors play a central role in the efficient transmission of electrical energy and enable the smooth operation of conveyor systems.

We have a wide range of different current collectors and high-current contacts on offer, which we can customise to suit the respective customer situation.

Our innovative current collectors are designed in such a way that they can adapt to different operating conditions. The contact pressure must be strong enough to maintain contact with the busbar, but at the same time flexible enough to adapt to the varying course of the busbar.

Regular inspections and maintenance work are crucial to ensure that the current collectors remain in optimum shape and guarantee trouble-free power transmission.

Our scope of delivery also includes telescopic current collectors and current collectors with spring clips made of certain copper alloys that are used in CDC systems in the automotive industry. In addition to the complete current collectors, you can also obtain the individual components from us as spare parts.

Telescopic current collectors

Our telescopic current collectors are available in various standard versions, whereby the telescopic and carbon brush components can be customised.

- Carbon brush:

- Cu-ETP: round | square | smooth

- Bronze: round | square | smooth | ribbed

- Amperage: 200 A | 400 A

- Telescope:

- Variable stroke

- Contact pressure 50 N | 100 N

- Version: fixed | swivelling

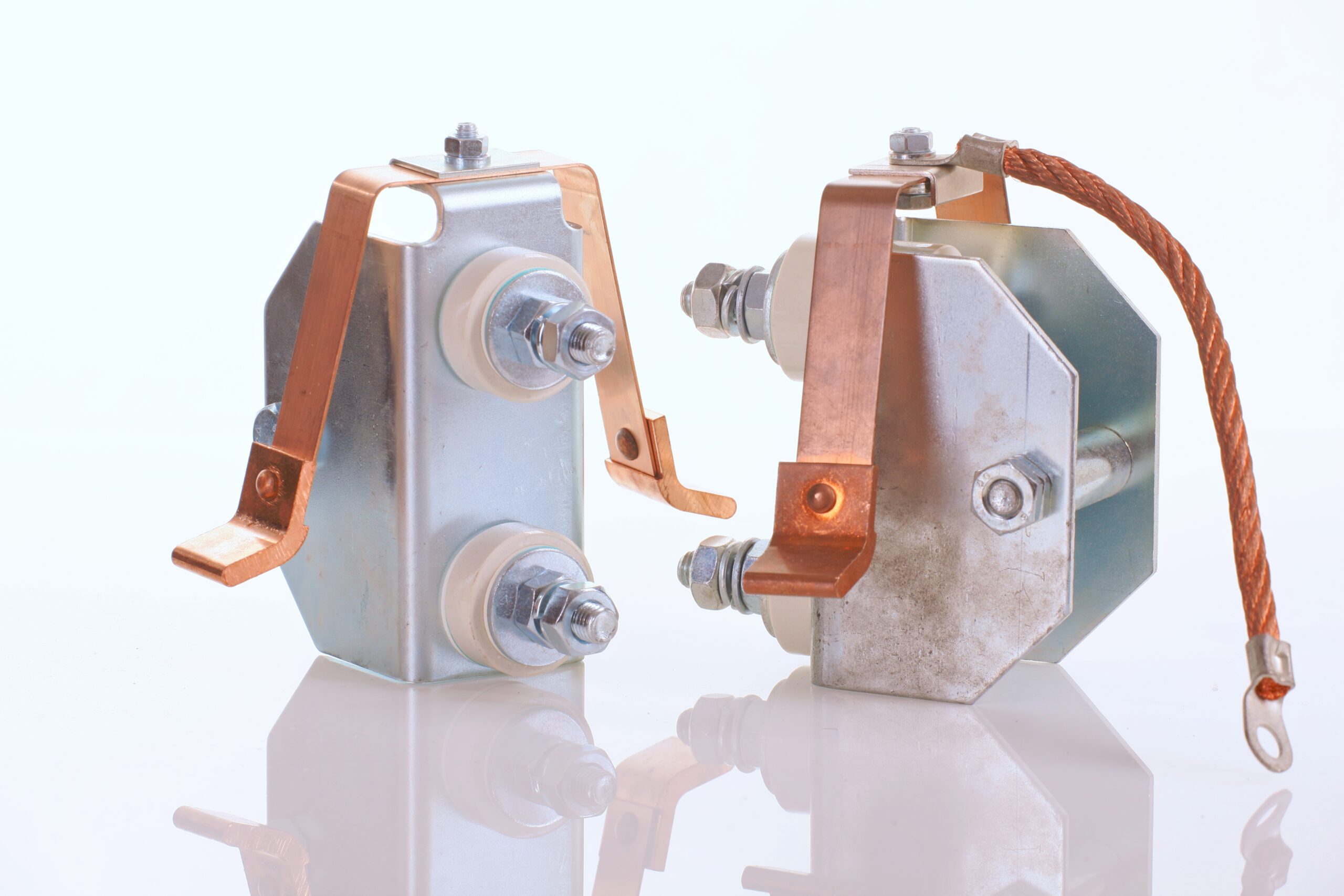

Current collector with spring clip

Current collectors with spring clips were specially designed for use in the automotive industry.

- Material:

- CuBe -– suitable for drying

- CuSn6 – not suitable for drying

- Contact:

- Carbon brush: Bronze | Cu-ETP

- Wear piece Cu-ETP

High-current finger contact

- Self-tensioning: The material rail slides in under its own weight, making it suitable for fully automatic system operation;

- Self-cleaning: The contact surfaces are cleaned by abrasion as the rail slides;

- Conductivity: Contact fingers and films packs made of E-Cu with guaranteed conductance values;

- Compact: small installation dimensions even with high currents;

- Easy to repair: individual parts can be easily replaced.