CNC cutting

Thanks to our ultra-modern machines, we always work with the highest precision and, as an innovation leader in the market for CNC contract manufacturing, we implement the individual wishes of our customers. Our services include CNC milling as well as CNC cutting.

Take advantage of the many years of experience and expertise of our trained specialists to fulfil your personal requirements for cutting work in the range of hundredths of a millimetre accurately and cleanly. Thanks to advanced CAD/CAM technology, we process sealing materials such as EPDM, Viton and Abil, elastomers, corrugated cardboard, films and foams as well as difficult-to-cut materials with the utmost precision and care using CNC cutting.

Your trusted partner for development, production and quality assurance

We accompany your project from development to delivery to the end customer. Our competent and committed team looks forward to every new challenge and will actively support you in your projects. Based on your sketch or a sample component, our in-house design office creates all relevant drawings and 3D models of the components that are to be subsequently manufactured by CNC cutting. This gives you an early impression of the finished end product and allows us to react flexibly to your change requests.

We utilise the synergy effects of qualified personnel, flat hierarchies and continuous improvement processes to support you as a reliable partner in CNC milling and CNC cutting. We attach great importance to open communication, short delivery times and transparent processes at fair conditions.

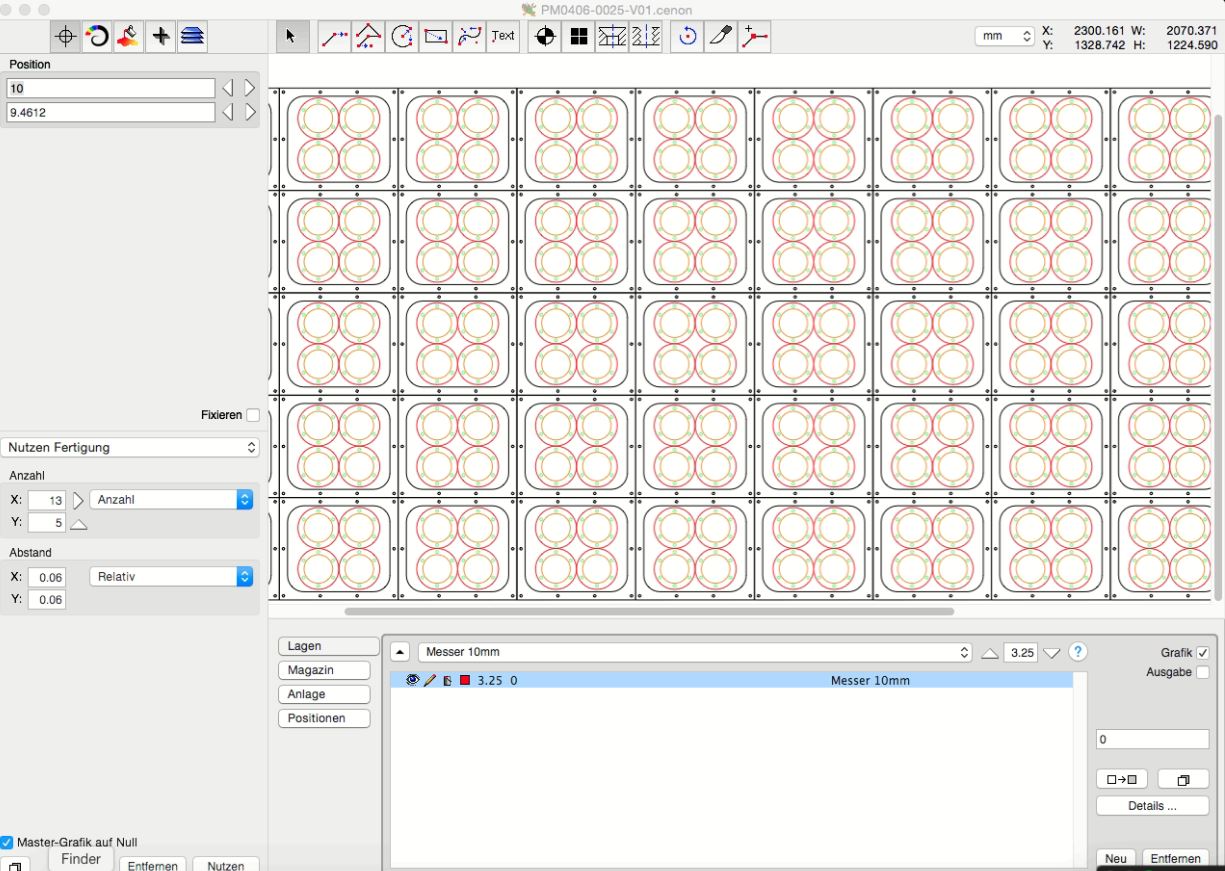

CNC cutting with an oscillating cutter head

The high-frequency oscillating tangential cutting head of our CNC cutting machine allows us to precisely produce complex contours and designs. In particular, materials such as EPDM seals, corrugated cardboard, templates made of thick films and other materials that are not suitable for machining processes can be processed effortlessly using our modern CNC cutting machine. We offer maximum flexibility with short delivery times. That’s because we manufacture at our sites in Friedberg and Ziemetshausen, where we also have a wide range of different raw materials at our disposal.

We produce individual items and series for our customers and partners with consistently high quality. We produce the most complex designs with tight tolerances of just a few hundredths of a millimetre in a fast and waste-optimised manner on a processing area of 4 x 2 metres. Thanks to the latest version of our special nesting software, we are able to manufacture in a particularly resource-efficient way thanks to free-form nesting. We pay attention to the sustainable use of raw materials and rely on advanced manufacturing processes.

EKK Anlagentechnik – everything from a single source

As a renowned company in the field of systems engineering as well as plastics and environmental technology, we offer you services that go beyond CNC cutting and CNC milling. We see ourselves as a reliable partner from consulting and development to component and systems production. A wide variety of joining methods such as welding, gluing, laminating or moulding are used during the production process.

Our highly motivated team is always available to provide you with comprehensive advice. Contact us and benefit from our wide range of services and products.

Frequently asked questions about CNC cutting

Which workpieces can be produced and processed with CNC cutting?

A CNC milling machine can be used to process technical sealing materials, stickers, films, paper, foams and much more. In contrast to industrially manufactured products made from these materials, we can execute customer-specific requirements.

Why is it worth using CNC technology?

CNC technology enables free-form shapes as well as complex, geometric shapes. These can be easily converted into a usable file format, imported directly onto the machine and produced in any quantity, both quickly and with repeatable accuracy.

Which machines does EKK Anlagentechnik use for CNC cutting?

For CNC cutting, we use the “VHF ActivePro 2040” 3-axis milling machine with an oscillating tangential cutter head. This milling machine is designed for a processing size of 4000 x 2000 millimetres.